Mold springs, often overlooked but crucial components in various industries, play a pivotal role in ensuring the functionality and durability of countless products and machines. These unassuming devices are designed to absorb shocks and vibrations, making them indispensable in automotive, aerospace, and manufacturing sectors. In this article, we will delve into the world of سنبه برش springs, exploring their significance, applications, and the innovative advancements that have made them a cornerstone of modern engineering.

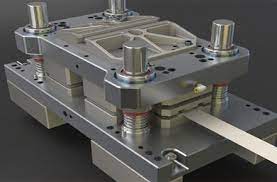

The Fundamental Functionality of Mold Springs: Mold springs, also known as die springs, are mechanical devices designed to store and release energy when subjected to compressive forces. They operate on the principle of elastic deformation, allowing them to absorb and dissipate energy in a controlled manner. This unique characteristic makes mold springs ideal for applications where consistent, reliable, and high-performance spring elements are required.

Applications in the Automotive Industry: One of the primary domains where mold springs find extensive use is the automotive industry. These springs are utilized in various components, such as clutch assemblies, suspension systems, and transmission modules. Mold springs contribute to smoother gear shifting, enhanced ride comfort, and improved vehicle stability. Their ability to withstand repetitive stress and maintain their performance over time makes them invaluable in the demanding environment of automobiles.

Aerospace Advancements: In the aerospace sector, mold springs play a critical role in ensuring the safety and reliability of aircraft components. These springs are employed in mechanisms like landing gear systems and cargo loading equipment. The aerospace industry’s stringent quality and safety standards demand components that can withstand extreme conditions, and mold springs rise to the occasion, providing the required reliability and performance.

Manufacturing Precision: Mold springs are equally important in the manufacturing realm. They are widely used in stamping and molding machines, where precise force control is essential. The ability to provide consistent force throughout their operational lifespan is a hallmark feature, ensuring high-quality output in manufacturing processes. Mold springs help maintain product integrity and reduce defects, contributing to increased productivity and cost-efficiency.